Fok and colleagues receive NIH grant for multidisciplinary device development study

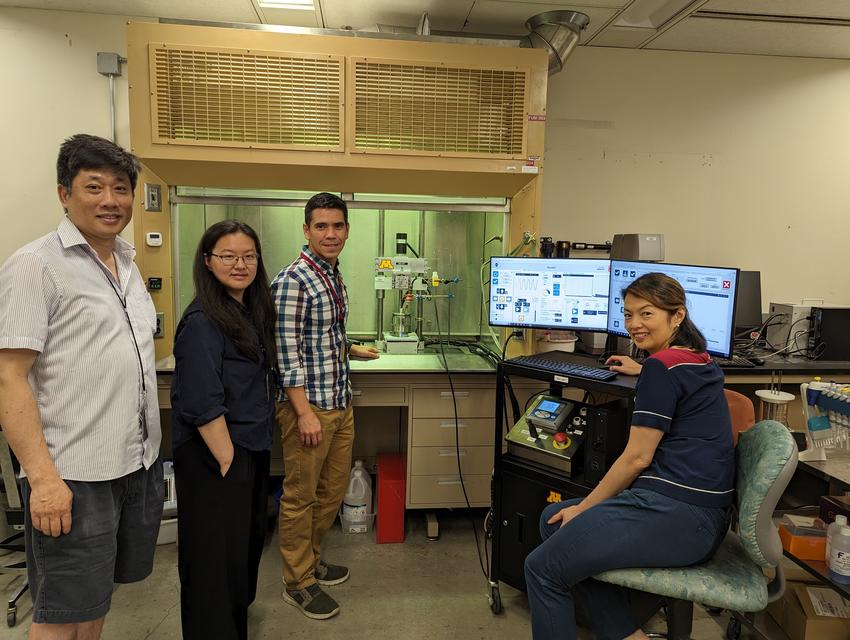

Alex Fok, BEng, PhD, director of the Minnesota Dental Research Center for Biomaterials and Biomechanics, received an NIH R61/R33 grant to develop a medical device development tool that accelerates the translation of new dental materials.

The four-year, $1.5 million grant for Clinically-calibrated Accelerated Fatigue Test for Predicting the Clinical Performance of Dental Restorative Materials lists Fok as the principal investigator and also includes Hooi Pin Chew, BDS, FDSRCS, PhD, associate professor of operative dentistry, Bruno Lima, DDS, PhD, assistant professor of basic sciences, and Lin Zhang, PhD, associate professor of biostatistics in the School of Public Health, as co-investigators.

The grant seeks to “reduce the need for lengthy and costly clinical studies, thus reducing the developmental costs and accelerating the translation of dental restorative materials from the benchtop to the chairside,” Fok explained.

Increasingly, new dental resin composites are expected to undergo a regulatory process through the Food and Drug Administration which requires a clinical trial. However, this process does not align with how materials are created.

“New restorative materials are developed at an alarming rate, and often when we start to receive the performance results from clinical trials about these materials, they may be replaced by new materials,” explained Chew. “Hence, there is a need to develop clinically relevant laboratory tests for restorative materials which may never quite replace clinical trials, but serve as an accelerated but impactful addition to full-fledged clinical trials.”

After years of collaboration and previous grant work in big data and electronic health records, the team decided the best path forward was a medical device development tool, or MDDT, “in the form of a laboratory test using simple specimens to predict the clinical performance of resin-composite restorations.”

In addition to the potential to be groundbreaking for the process of FDA approval of resin-composite restorations, the project is particularly exciting for its multidisciplinary approach to scientific discovery.

“This test involves subjecting model resin-composite restorations (Operative Dentistry) to accelerated fatigue (Mechanical Engineering) and biofilm (Microbiology) challenges to simulate degradation in the oral environment,” Fok explained. “It also involves calibration and validation of the statistical failure models (Statistics) using clinical data (Data Mining) from the BigMouth Dental Data Repository.”

The multidisciplinary approach is what stoked the interest of Fok’s collaborators. “As a basic science researcher, I spend much of my time trying to understand the basic biological processes involved in bacterial biofilm formation and development,” explained Lima. “This collaboration gives us a unique opportunity to apply some of the knowledge we acquire to more translational and applied research, contributing more directly to oral health.”

Chew believes this collaborative spirit will enhance the outcome and its reception. “This effort was put together by a lead who is a mechanical engineer, and it involves a clinical researcher, a microbiologist and a statistician,” she said. “The objective and methodology of this project are rigorous in all respects, and could be expressed in a way that resonates with many.”

It certainly resonates with Zhang, who agreed to the collaboration with dentistry colleagues based on prior experiences with Fok. “This project will involve survival analysis to aid in developing this new tool for dentistry practice, and I am looking forward to it,” she said.

And the opportunity to grow is exciting. “As a trained microbiologist, I am excited to learn more from my biomaterials colleagues as we work toward developing a tool that can be used to test new composite materials and ultimately help increase the longevity of composite restorations,” said Lima.

But most of all, the team looks forward to creating a validated, successful tool that changes how materials are approved.

“We are looking forward to the proposed MDDT being accepted by the FDA, so that it can be used by manufacturers to help accelerate the development and translation of next-generation dental biomaterials,” said Fok.