Innovation with a purpose | A message from the Dean

One of the pleasures I have as Dean is to shine light on the many wonderful achievements of our faculty, staff and learners. As a prosthodontist, I have found relationships with dental laboratory technicians (DLTs) to be invaluable. When providing patient care, it was common for me to go to the lab and ask questions or get assistance. I have been fortunate to practice in academic settings with DLTs readily available, so for me, there’s no question that we would have a team of DLTs to provide support to our faculty and learners. What is rare is to have DLTs that go above and beyond and become innovators.

During this early period of the 21st century, prosthetic workflows have become increasingly dependent on digital processes. However, removal prosthetics have lagged behind because of the lack of consistent, efficient, economical and esthetic outcomes that surpass traditional workflows.

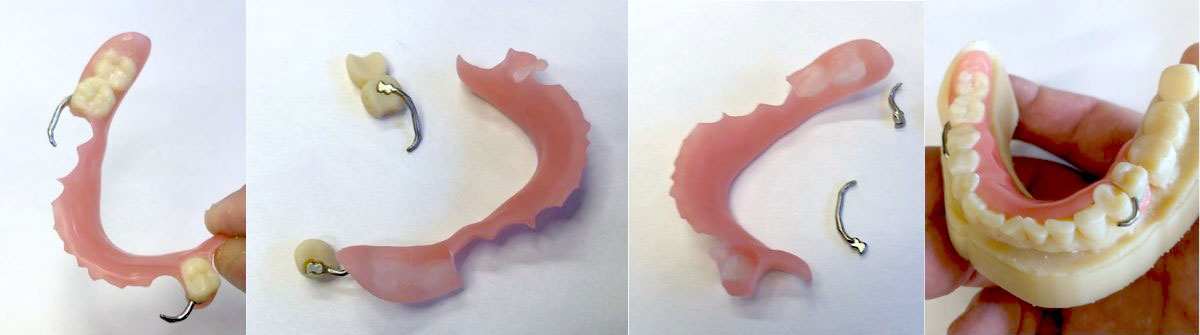

Our own John Madden, CDT, (DLT) and Paul Olin, DDS, MS (Division of Prosthodontics) have made a breakthrough in one of these processes by creating a digital workflow that creates a 3-D printed removable with a wrought wire. This is an important innovation, as it creates an opportunity to reduce oral health inequities, rather than widening the gap as other digital workflows have commonly done because innovations like implants and digitally fabricated crowns can cost beyond the financial limits of some patients. A treatment option for people with limited finances is an interim removable partial denture. Having a 3-D printed format of that model means all patients, irrespective of finances, will be able to access a new, innovative and digital treatment modality.

Congratulations to John and Dr. Olin for this innovation! I wish them much success on their pending international patent of this process.